For field as well as fleet service applications, you can count upon the benefits which air and gas compressors provide. The demand for such compressors has skyrocketed in the last few years. These make perfect choice for emergency production line requirements, pneumatic applications along with several other situations where there is scarcity of electrical power. These air and gas compressors provide air as and when and where they need be. They feature truck be mounting and comprise idle engine control, electronic ignition, an OSHA accredited fully enclosed belt guard, a 30 gallon ASME receiver along with a weather-resistant powder coat finish.

Air and gas compressors can easily be configured to suit a wide range of high pressure application for both air as well as compressible gases. There is a wide variety of options of such compressors to choose from. Starting from a basic compressor to completely integrated compressor packages solution for high pressure gas or air. These can be incorporated with ancillary items such as air or gas driers and nitrogen generation into the scope of supply. These air and gas compressors units are designed to comply with international standards for a broad spectrum of applications and industries.

Oil Free Reciprocating Piston Compressors are counted among the most reliable solutions for biogas and methane based fuel gas, hydrogen as well as other gases. These are designed for round the clock industrial service with minimal long over haul intervals and maintenance cost. These compressors have the ability to work in the most efficient as well as cost-effective way under challenging and demanding site conditions.

Oil Free Reciprocating Piston Compressors are counted among the most reliable solutions for biogas and methane based fuel gas, hydrogen as well as other gases. These are designed for round the clock industrial service with minimal long over haul intervals and maintenance cost. These compressors have the ability to work in the most efficient as well as cost-effective way under challenging and demanding site conditions.

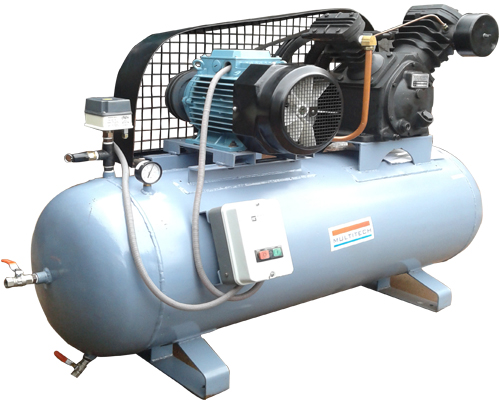

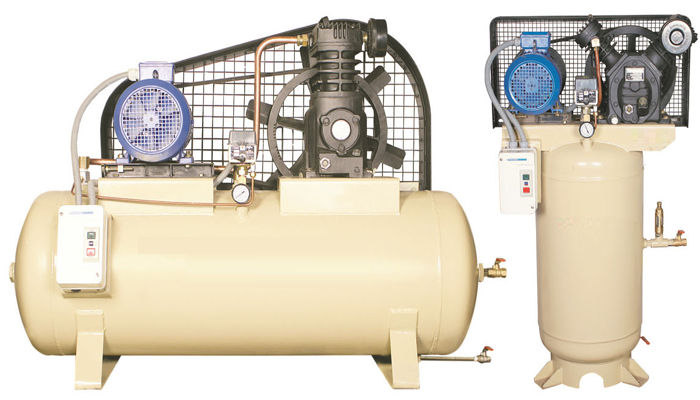

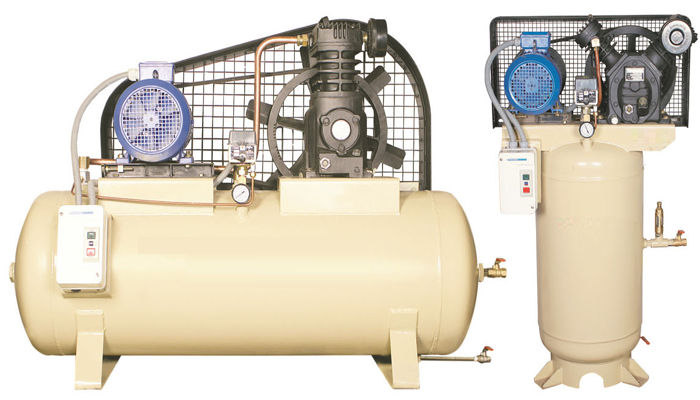

A reciprocating air compressor or industrial air compressor refers to a positive displacement compressor that makes use of a cylinder and crankshaft-driven piston for compressing the air. A single stage reciprocating piston compressor functions by drawing the air into cylinder. Here it is compressed in a single stroke of piston of near about 120 PSI before sending to a storage tank. A two stage compressor comprises of an additional step where the air is compressed again, smaller piston to a pressure which can go up to 175 PSI.

A reciprocating air compressor or industrial air compressor refers to a positive displacement compressor that makes use of a cylinder and crankshaft-driven piston for compressing the air. A single stage reciprocating piston compressor functions by drawing the air into cylinder. Here it is compressed in a single stroke of piston of near about 120 PSI before sending to a storage tank. A two stage compressor comprises of an additional step where the air is compressed again, smaller piston to a pressure which can go up to 175 PSI.

Cast iron and oil lubricated air compressors are heavier as well as more expensive however are quieter and lasts for a long time. No matter whether you are DIY user or commercial user then opting for cast iron and oil lubricated compressor makes for the apt choice. If you shell out more money for oil lubricated model now, you will get better payback in the long run. Purchasing two cheaper compressors rather than one quality model will lead to more frustration and expense.

Oil Lubricated Reciprocating Piston Compressors are used where high compression ratio is needed at every stage without high flow, and the process fluid is dry. Installing these compressors is one of the best ways to save money in long run.

Oil Lubricated Rotary Screw Compressors are one of the most commonly used air compressors for medium to high flow of nitrogen applications. Rotary screw compressors are positive displacement compressors. It is the single stage widely used compressor in the industry.

Oil Lubricated Rotary Screw Compressors are one of the most commonly used air compressors for medium to high flow of nitrogen applications. Rotary screw compressors are positive displacement compressors. It is the single stage widely used compressor in the industry.

The rotary screw compressors come with two rotors encased within housing, also known as an air end. Ambient air enters the air end where it is compressed by the two rotors. Then the oil is injected into the air end for a creating a seal and for the purpose of cooling. When it comes to maintenance, it is simple and easy. Preventative maintenance steps usually include changing of oil or air separator; oil; air filters and oil filters. There are several designs which are available for the controlling the capacity of air compressor. These units can operate in either modulation; no load or load and variable speed. It is the variable speed technology which is considered as the most energy efficient method of operating air compressor.

Oil Lubricated Rotary Screw Compressors are highly energy efficient and are designed for constant duty making them the apt choice for nitrogen generators which operate round the clock. These are apt for high pressure applications.

These compressors are found in variety of applications. Oil free rotary screw compressors are used in several production as well as service facilities where pure and clean air is needed. Majority of users of the compressor are in the fields of pharmaceuticals, food, electronics and textiles. These are also used in research facilities as well as hospitals.

These compressors are found in variety of applications. Oil free rotary screw compressors are used in several production as well as service facilities where pure and clean air is needed. Majority of users of the compressor are in the fields of pharmaceuticals, food, electronics and textiles. These are also used in research facilities as well as hospitals.

Thousands of oil free rotary screw compressors are already being used across different industries. As a matter of fact, these are installed in some of the most important and largest manufacturing companies. There are several designs of such type of compressors available from which you can choose the one as per your needs, preference and budget.

Reliability:

There are various air compressors available in the market out of which the oil-free air compressors are used to give oil-free compressed air. Such type of compressors are used in critical operations, where the products are contaminated if brought in context to small amount of oil. The medical oil-less air compressors are used to generate air for breathing applications in the medical domain. The medical oil-less air compressor should be used to ensure zero percent of oil contamination within the production process. These compressors are generally used in hospitals, pharmaceutical applications, and laboratories. These air compressors produce the clean air that is crucial for some applications to increase productivity and reduce the process down time.

There are various air compressors available in the market out of which the oil-free air compressors are used to give oil-free compressed air. Such type of compressors are used in critical operations, where the products are contaminated if brought in context to small amount of oil. The medical oil-less air compressors are used to generate air for breathing applications in the medical domain. The medical oil-less air compressor should be used to ensure zero percent of oil contamination within the production process. These compressors are generally used in hospitals, pharmaceutical applications, and laboratories. These air compressors produce the clean air that is crucial for some applications to increase productivity and reduce the process down time.

There are two major categories defined for industrial air compressor, they are positive displacement and dynamic compressors. The positive displacement is further classified as oil injected and oil less compressors. Air compressor is a device that transforms the power into potential energy stored in pressurized air. The positive displacement compressors operate by forcing air into a chamber where the volume is reduced to compress the air. The common types of positive displacement compressors are piston-type, rotary screw, and vane compressors. The common applications of industrial air compressor are providing high-pressure clean air to fill the gas cylinders, submerged surface supplied divers, and power pneumatic tools.

There are two major categories defined for industrial air compressor, they are positive displacement and dynamic compressors. The positive displacement is further classified as oil injected and oil less compressors. Air compressor is a device that transforms the power into potential energy stored in pressurized air. The positive displacement compressors operate by forcing air into a chamber where the volume is reduced to compress the air. The common types of positive displacement compressors are piston-type, rotary screw, and vane compressors. The common applications of industrial air compressor are providing high-pressure clean air to fill the gas cylinders, submerged surface supplied divers, and power pneumatic tools.

The non-lubricated air compressors satisfies the need of the industries that require the oil-free air round the clock. The applications of these air compressors are in various industries such as sugar, textile, food processing, pharmaceuticals, and cement industries. The advantages of non-lubricated air compressor are that you do not need to fill oil on daily basis, reduces the disposal cost, and reduces the discharge filtration. You will find that many non-lubricated air compressors run at relatively low operational speed. These compressors are provided by many manufacturers. Therefore, while purchasing it you should ensure that you go through the details of each manufacturer and select the best one.

The non-lubricated air compressors satisfies the need of the industries that require the oil-free air round the clock. The applications of these air compressors are in various industries such as sugar, textile, food processing, pharmaceuticals, and cement industries. The advantages of non-lubricated air compressor are that you do not need to fill oil on daily basis, reduces the disposal cost, and reduces the discharge filtration. You will find that many non-lubricated air compressors run at relatively low operational speed. These compressors are provided by many manufacturers. Therefore, while purchasing it you should ensure that you go through the details of each manufacturer and select the best one.

The introduction of oil free air compressor has benefitted the industries such as pharmaceuticals, food and beverages, and electronics and textiles. You will find the growing demand of high-quality compressed air in chemical and process engineering applications. It generates identical compressed air. The air within the compressor system is also oil-free. Therefore the air inside the compressor system should be oil-free. Oil-free air compressors are less expensive, lighter in weight, produces as much air as required. These compressors need less maintenance and are more durable. Because the oil-free air compressors are pre-lubricated; therefore, the constant maintenance is not required.

The introduction of oil free air compressor has benefitted the industries such as pharmaceuticals, food and beverages, and electronics and textiles. You will find the growing demand of high-quality compressed air in chemical and process engineering applications. It generates identical compressed air. The air within the compressor system is also oil-free. Therefore the air inside the compressor system should be oil-free. Oil-free air compressors are less expensive, lighter in weight, produces as much air as required. These compressors need less maintenance and are more durable. Because the oil-free air compressors are pre-lubricated; therefore, the constant maintenance is not required.

The introduction of oil free scroll air compressor has benefitted the industries such as pharmaceuticals, food and beverages, and electronics and textiles. You will find the growing demand of high-quality compressed air in chemical and process engineering applications. It generates identical compressed air.

The introduction of oil free scroll air compressor has benefitted the industries such as pharmaceuticals, food and beverages, and electronics and textiles. You will find the growing demand of high-quality compressed air in chemical and process engineering applications. It generates identical compressed air.

The breathing air compressor systems are ideal for firefighting, diving, military, and medical applications where reliable pure breathing air is required for life safety. These are also used for fire departments and best suited for recreational divers, small diving clubs and diving boats because they are designed as lightweight and compact. Generally the breathing air compressors are used as emergency services as well as in industrial markets. Moreover, it has been found that the these are also used for industrial purposes such as spray painting, asbestos removal, and in the regions where there is environmental pollution.

The breathing air compressor systems are ideal for firefighting, diving, military, and medical applications where reliable pure breathing air is required for life safety. These are also used for fire departments and best suited for recreational divers, small diving clubs and diving boats because they are designed as lightweight and compact. Generally the breathing air compressors are used as emergency services as well as in industrial markets. Moreover, it has been found that the these are also used for industrial purposes such as spray painting, asbestos removal, and in the regions where there is environmental pollution.

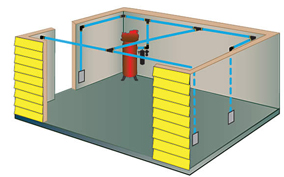

The ideal use of garage air compressor is sanding, cutting, grinding, painting, polishing, and inflating. With the help of this compressor all these tasks become easier and consumes less time. It is used for inflating tires of car or bicycle as well as inflatable toys. Such air compressors are also used for pressure cleaning and powering air tools. There are many manufacturers in the market supplying or manufacturing garage air compressor. However, while purchasing the compressor you should browse for the top manufacturer and ensure there is no leakage. These are used for home, industrial, and commercial applications.

The ideal use of garage air compressor is sanding, cutting, grinding, painting, polishing, and inflating. With the help of this compressor all these tasks become easier and consumes less time. It is used for inflating tires of car or bicycle as well as inflatable toys. Such air compressors are also used for pressure cleaning and powering air tools. There are many manufacturers in the market supplying or manufacturing garage air compressor. However, while purchasing the compressor you should browse for the top manufacturer and ensure there is no leakage. These are used for home, industrial, and commercial applications.

Reciprocating air compressor is a positive-displacement compressor using pistons designed by crankshaft to give gases at high pressure. Such compressors are used in oil refineries, gas pipelines, chemical plants, natural gas processing plants, and refrigeration plants. An important application of the reciprocating air compressor is blowing plastic bottles made of polyethylene terephthalate (PET). These compressors are also used on small compressors to assist air-cooled systems. It has been found that these are the compressors which are mostly used for refrigeration and air conditioning application. You will find these efficient and reliable. The manufacturers design these with utmost care and skill.

Reciprocating air compressor is a positive-displacement compressor using pistons designed by crankshaft to give gases at high pressure. Such compressors are used in oil refineries, gas pipelines, chemical plants, natural gas processing plants, and refrigeration plants. An important application of the reciprocating air compressor is blowing plastic bottles made of polyethylene terephthalate (PET). These compressors are also used on small compressors to assist air-cooled systems. It has been found that these are the compressors which are mostly used for refrigeration and air conditioning application. You will find these efficient and reliable. The manufacturers design these with utmost care and skill.

Piston air compressors are identical to reciprocating air compressors and are used or ideally suited to variable air demand in low to medium volumes. These compressors are ideal for paint and panel, automotive, trade, industrial, plastics, food and beverages, and manufacturing companies. These compressors are used in applications where compressed air requirements are low. These air compressors are ideal for heavy-duty industrial applications and provide powerful performance as well as long lasting durability. In other words, you can use these piston air compressors where a high-level supply of compressed air is needed.

Piston air compressors are identical to reciprocating air compressors and are used or ideally suited to variable air demand in low to medium volumes. These compressors are ideal for paint and panel, automotive, trade, industrial, plastics, food and beverages, and manufacturing companies. These compressors are used in applications where compressed air requirements are low. These air compressors are ideal for heavy-duty industrial applications and provide powerful performance as well as long lasting durability. In other words, you can use these piston air compressors where a high-level supply of compressed air is needed.

Piston air compressors are identical to reciprocating air compressors and are used or ideally suited to variable air demand in low to medium volumes. These compressors are ideal for paint and panel, automotive, trade, industrial, plastics, food and beverages, and manufacturing companies. These compressors are used in applications where compressed air requirements are low. These air compressors are ideal for heavy-duty industrial applications and provide powerful performance as well as long lasting durability. In other words, you can use these piston air compressors where a high-level supply of compressed air is needed.

Piston air compressors are identical to reciprocating air compressors and are used or ideally suited to variable air demand in low to medium volumes. These compressors are ideal for paint and panel, automotive, trade, industrial, plastics, food and beverages, and manufacturing companies. These compressors are used in applications where compressed air requirements are low. These air compressors are ideal for heavy-duty industrial applications and provide powerful performance as well as long lasting durability. In other words, you can use these piston air compressors where a high-level supply of compressed air is needed.

PET Blowing High Pressure Boosters Air Compressors Packages have caught the attention of many across the globe. These products are designed taking into consideration the standards of the domestic industry. These are highly popular for their strong built and rigidness, and thus are appreciated by customers looking for quality products. These products are used extensively in heavy duty industries because of the benefits they bring along.

Features of PET Blowing High Pressure Boosters Air Compressors Packages:

If you are considering buying one and wondering how to go about it then reading further might help you make a well-informed and smart decision. You can now choose from differently highly advanced technologies of air compression, which now comprise of outstanding performance of reciprocating four stage compressors for choosing the one which best meets the productions needs of your plant.

Installing these machines make for an apt choice for those who want to reach new levels of success in the global marketplace. Keeping production lines running with minimum interruption and smoothness is important. Downtime, whether unscheduled or scheduled can prove costly. Performance and reliability of these products is second to none.

Buying and installing PET Blowing High Pressure Boosters Compressors Packages is a decision which will reap benefits in years to come. These are energy efficient and robust machines which can ease the entire maintenance process. Though many find these expensive but such products can be of great help in the overall working of the industry.

These are an excellent choice for many different industries which need high air volume that too at high pressure. Using high quality totally frame supported modular add on unites which are progressive enough to be mounted as and when the requirement increases, these products are designed keeping in mind the best technology.